Researchers at Saudi Arabia's King Abdullah University of Science and Technology (KAUST) have shown how imploding bubbles in a solution can grow single crystals of perovskites especially suited for solar applications.

The researchers explain that hybrid perovskite materials can easily be fabricated on a large scale from a solvent solution. However, this process typically produces polycrystalline perovskite films that have a smaller solar light conversion efficiency than monocrystalline materials because the boundary between crystalline grains leads to losses. In particular, growth of single-crystalline perovskite solar cell films has not yet been achieved on top of other materials, which is a requirement for practical devices.

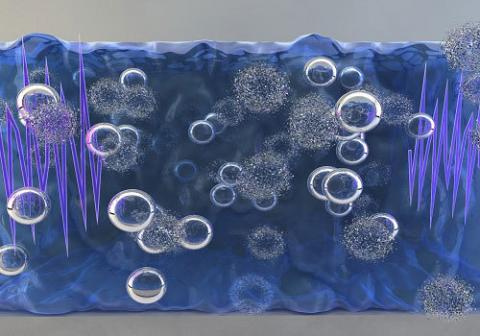

In this work, the KAUST team achieved the fabrication of single-crystalline perovskite thin films by applying ultrasonic pulses to the growth solution. The pulses induce tiny bubbles that implode after a short time, releasing energy into the surrounding solution. If a bubble is close to the substrate surface, the energy from the implosion creates tiny jets within the growth solution that are projected towards the substrate. Those jets induce the nucleation of perovskite crystals on the surface.

The films grown by this process are said to be remarkably uniform and monocrystalline. Also, because of the directional impact of the liquid jets on the surface, the growth process is independent of the substrate properties and therefore leads to a favorable uniform orientation of the crystals. This alignment means they can support the transport of electrical charges across the device.

The thin films show very good conversion efficiencies. In test devices, a conversion efficiency of 6.5% was achieved, which is considerably higher than the 5.6% previously achieved from comparable polycrystalline samples.

There are further hurdles, however, as the team noted. 'The biggest challenge of our method is the limited lateral dimensions that we can reach, which are only about two millimeters. The next step of our study is to improve the growth to reach centimeter-scale monocrystalline films or even larger sizes, which is essential for the large scale application of these monocrystalline films in industry'.