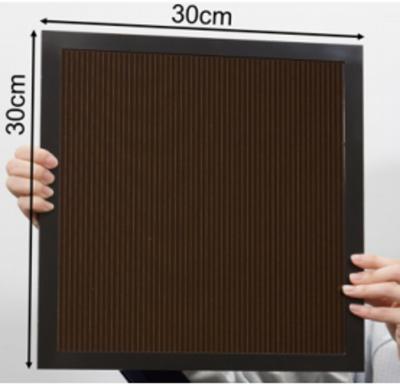

Panasonic Corporation has achieved an energy conversion efficiency of 16.09% for a perovskite solar module (Aperture area 802 cm2: 30 cm long x 30 cm wide x 2 mm thick) by developing lightweight technology using a glass substrate and a large-area coating method based on inkjet printing.

This was carried out as part of the project of the New Energy and Industrial Technology Development Organization (NEDO), which is working on the "Development of Technologies to Reduce Power Generation Costs for High-Performance and High-Reliability Photovoltaic Power Generation" to promote the widespread adoption of solar power generation.

By focusing on the inkjet coating method that enables the raw material to be coated precisely and uniformly, Panasonic applied that technology to each layer of the solar cell including perovskite layer on glass substrate and realized high power conversion efficiency for a large-area module.

- Improving component of perovskite precursor for suitable for ink-jet coating: among the atomic groups that formed perovskite crystal, methylamine has a thermal stability issue during the heating process during module production (methylamine is removed from perovskite crystal by heat, as a result, a certain part of crystal is destroyed). By altering certain part of methylamine into Formamidinium, Cesium, Rubidium that have appropriate atom diameter size, they revealed this method is efficient for crystal stabilization and leads to contribute to high power conversion efficiency.

- Control of concentration, coating amount and coating speed of perovskite ink: in the thin film forming process with inkjet coating method, there is the flexibility for coating pattern, while dot patterning of material and crystallization uniformity over each layer surface are essential. To satisfy these requirements, both by tuning the concentration of perovskite ink to certain content and by precisely controlling coating amount and speed during printing process, they realized high power conversion efficiency of large-area module.

By optimizing these technologies through coating process in each layer formation, Panasonic succeeded in enhancing crystal growth and improving the uniformity for thickness and crystal layer. As a result, they achieved the power conversion efficiency of 16.09% and took a step forward to practical application.

Going forward, NEDO and Panasonic plan to continue to improve perovskite layer materials, aiming to achieve high efficiency comparable to that of crystalline silicon solar cells and establish technologies for practical application in new markets.