A research team composed of scientists from Michigan State University and University of Michigan has deployed a new approach to growing all inorganic lead-free halide perovskites.

"Epitaxial growth has long since revolutionized the study of many electronic materials including silicon, oxide perovskites, and III-V semiconductors," said Richard Lunt, an Associate Professor at Department of Chemical Engineering and Materials Science, Michigan State University who has supervised the project. "There is very little known about the epitaxial growth of halide perovskites, but these exciting materials hold enormous potential. This has motivated us to explore this entirely new research area."

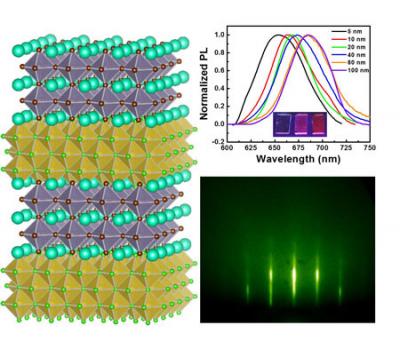

Based on the precise manipulation of phase and monolayer thickness, the team has fabricated the first epitaxial multilayer quantum well system incorporating a halide perovskite. Such a demonstration could lead to their application in various advanced electronics including lasers, photodetectors, and transistors.

"A key factor for epitaxial growth is to control the lattice misfit between the substrates and epitaxy," says Lili Wang, a Research Associate in Lunt's lab who has led the experimental part of this work. "In our current research, we use low-cost alkali metal halide salts as substrates. Previously, we had developed a method to control the lattice misfit by alloying different types of alkali metal halide salts."

By deploying this alloy approach, the researchers can achieve near-zero lattice misfit and adjust the lattice constant of their substrates. This provides a lot of flexibility on the selection of substrates.

For the Purpose of fabricating devices, they further developed an epitaxial lift-off method to transfer the epitaxial film to any substrate of interest.

The solar cell device fabricated with the transferred single crystalline film as the absorber layers demonstrated both higher photocurrent and photovoltage than the control devices fabricated with amorphous films thanks to the improved crystallinity and film ordering achieved by epitaxial growth.

Their devices suggested that the power conversion efficiency of devices fabricated with this halide perovskite composition is likely to exceed at least 10%. "More importantly, after transferring we are able to reuse the substrates for the next round of epitaxial growth. It can further reduce the cost of this method," Wang emphasizes.