Researchers from China's Henan University and Chinese Academy of Sciences (CAS) have reported an extremely efficient carbon electrode perovskite solar cell that reportedly achieves a power conversion efficiency of 20.8% while providing enhanced stability.

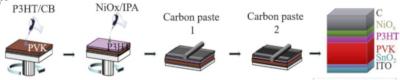

Schematic diagram of the fabrication process of bilayer HTL carbon electrode perovskite solar cells. Image from the study published in Journal of Materials Research and Technology

Commonly used metal contact electrodes can promote the degradation of perovskite solar cells due to the diffusion of metal impurities across the interfaces. This issue could be theoretically overcome by replacing the metal contact with carbon electrodes, which are highly promising for commercialization due to their ambient pressure processability based on industrially established printing techniques. The problem is, however, that perovskite solar cells based on carbon electrodes lead to performance losses at the point where the carbon electrode meets the perovskite layer.

“For carbon electrode perovskite solar cells, the interfacial contact between carbon electrode and perovskite is of great significance to the performance of solar cells,” the scientists said in their recent study. “Most of inorganic hole transport layers (HTLs) are based on dispersive nanoparticles those could easily aggregate to form rough contact with both perovskite and the viscous carbon paste; the holes collection is thus negatively affected.”

They tried to solve this issue by placing an organic semiconducting polymer called polythiophene (P3HT) between perovskite and an HTL made of nickel(II) oxide (NiOx) and reported that this organic/inorganic planar HTL structure has superior electrical contact for carbon electrode perovskite solar cells.

“The organic P3HT layer enables effective moisture-inhabitation and densely contacted interface with matched energy-level alignment with perovskite, while the stable NiOx nanoparticle layer further protects P3HT from being corroded by carbon paste so that we can further optimize carbon blade-coating deposition to form densely contact with HTL,” the team explained.

The research group built the cell with a substrate made of indium tin oxide (ITO), a tin(IV) oxide (SnO2) buffer layer, a perovskite absorber, the P3HT layer, the HTL made of NiOx, and a carbon electrode. The electrode is based on a carbon paste containing carbon black and graphite powder provided by Saidi Technology Development Inc., China. “Carbon electrode was prepared by blade-coating process and the wet film was annealed at 110 C for 5 min,” the team explained.

The scientists compared the performance of the solar cell with that of a reference device without the modified anode buffer interfaces, which they say are able to facilitate charge collection.

The champion solar cell built with these interfaces achieved a power conversion efficiency of 20.8%, an open-circuit voltage of 1.15 eV, a short-circuit current of 22.9 mA/cm2, and a fill factor of 78.8%.

“This efficiency is among the top values of carbon electrode perovskite solar cells; a champion efficiency of 22% was reported from assembly of semi-cells with carbon electrode substrate,” they stated. “The operational stability of this cell obviously improves because of an introduction of the hydrophobic P3HT layer and the dense carbon pre-covering”. The reference device, by contrast, reached an efficiency of only 13.4%.