A research team, led by Los Alamos National Laboratory, has designed a simple solution for fabricating stable perovskite solar cells that is said to overcome the key bottleneck to large-scale production and commercialization of perovskite solar cells.

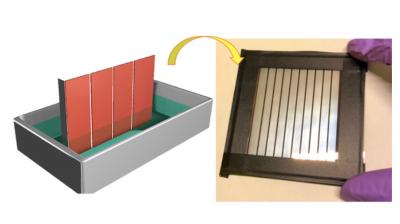

A new dipping process using a sulfolane additive creates high-performing perovskite solar cells. Image: LANL

A new dipping process using a sulfolane additive creates high-performing perovskite solar cells. Image: LANL

The Los Alamos team, in collaboration with researchers from National Taiwan University (NTU), invented a one-step spin coating method by introducing sulfolane as an additive in the perovskite precursor, or the liquid material that creates the perovskite crystal through a chemical reaction. As in other fabrication methods, that crystal is then deposited on a substrate.

The new process allowed the team to produce high-yield, large-area photovoltaic devices that are highly efficient in creating power from sunlight. These perovskite solar cells also have a long operational lifetime.

'Our work paves the way for low-cost, high-throughput commercial-scale production of large-scale solar modules in the near future,' said Wanyi Nie, a research scientist fellow in the Center of Integrated Nanotechnologies. Nie is the corresponding author of the paper. 'We were able to demonstrate the approach through two mini-modules that reached champion levels of converting sunlight to power with greatly extended operational lifetimes. Since this process is facile and low cost, we believe it can be easily adapted to scalable fabrication in industrial settings.'

Through a simple dipping method, the team was able to deposit a uniform, high-quality perovskite crystalline thin film covering a large active area in two mini-modules, one of about 16 square centimeters and the other nearly 37 square centimeters. Fabricating uniform thin film across the entire photovoltaic module's area is essential to device performance.

The mini modules achieved a power conversion efficiency of 17.58% and 16.06%, respectively'among the top reported to date. The power conversion efficiency is a measure of how effectively sunlight is converted into electricity.

For other perovskite fabrication methods, one of the major roadblocks to industrial-scale fabrication is their narrow processing window, the time during which the film can be laid down on the substrate. To get a uniform crystalline film that's well bonded to the layer below it, the deposition process has to be strictly controlled within a matter of seconds.

Using sulfolane in the perovskite precursor extends the processing window from 9 seconds to 90 seconds, forming highly crystalline, compact layers over a large area while being less dependent on the processing conditions.

The sulfolane method can be easily adapted to existing industrial fabrication techniques, which helps to pave the path toward commercialization.