Researchers from South Korea's Institute for Basic Science (IBS), Gwangju Institute of Science and Technology and Korea University have developed perovskite micro cells with a power conversion efficiency of 20.1% that can be used in colored solar windows.

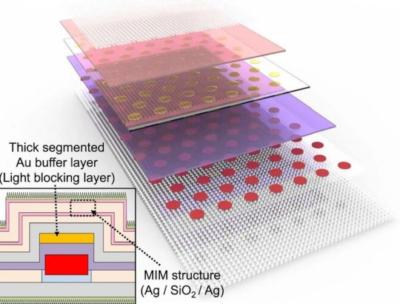

the colored solar window with the metal'insulator'metal (MIM) resonant structure. The inset shows a cross-sectional view of the perovskite microcell in the colored solar window. Image from Nature Communications

the colored solar window with the metal'insulator'metal (MIM) resonant structure. The inset shows a cross-sectional view of the perovskite microcell in the colored solar window. Image from Nature Communications

The devices were built using a lift-off-based patterning approach based on swelling-induced crack propagation.

In the process, the perovskite film was deposited by spin-coating on layers made of poly(methyl methacrylate) (PMMA) and polyimide (PI) that were prepatterned via oxygen plasma etching. A top silicon oxide (SiO2) layer is utilized as an etch stop layer for the dry etching of PMMA/PI layers and is finally wet-etched using a buffered oxide etchant (BOE).

After cracks propagate along the edge, the PI/perovskite layers are detached from the substrate without any fractures or partial delamination of the patterned films on the substrate.

'During the prepatterning of the PMMA/PI layers, the substrate becomes hydrophilic owing to oxygen plasma. Thus, the perovskite precursor can be spread over the entire substrate,' the scientists said, noting that this step allows the deposition of a perovskite film with a uniform thickness, a flat surface, and conformal coverage.

The micro cells were built with an insulation layer deposited on the ETL to prevent a direct contact between the ETL and the hole transport layer (HTL (violet). The insulation layer was then patterned and etched to expose the ETL inside the microcell area. The perovskite layer was deposited and patterned after the deposition of the HTL and top electrode.

The scientists tested 458 perovskite micro cells with a diameter of 100 μm and an electrode area of 9 mm2 and found that the best performing device, under standard illumination conditions, achieved an efficiency of 20.1%, an open-circuit voltage of 1.16'V, a short-circuit current density of 22.5'mA/cm2, and a fill factor of 77%. The micro cells also showed a light utilization efficiency of 4.67 and a color rendering index of 97.5 %.

The researchers used the devices to also build a prototype of a solar window which they say has vivid colors and high color purity. The window was fabricated with metal'insulator'metal structures and moth-eye-inspired nanostructures.