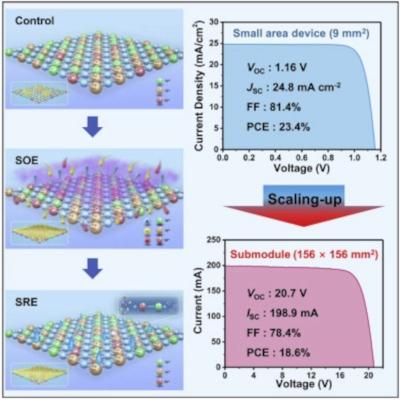

Researchers led by Prof. LIU Shengzhong from the Dalian Institute of Chemical Physics (DICP) of the Chinese Academy of Sciences (CAS) have developed a facile surface redox engineering (SRE) strategy for vacuum-deposited NiOx to match the slot-die-coated perovskite, and fabricated high-performance large-area perovskite submodules.

Inverted PSCs could be even more valuable than their normal counterparts because the former have easily-mitigated hysteresis behavior and long-term durability. NiOx has been demonstrated as a promising hole transport material for inverted PSCs. But for most vacuum-processed NiOx films, the relatively hydrophobic surface attenuates the adhesion of perovskite ink, making it challenging to deposit large-area perovskite films.

In addition, the surface chemistry of NiOx is rather complex as a large number of high-oxidative-state Ni species and chemically reactive hydroxyls can decompose perovskites, leading to an interface energy barrier and noncapacitive hysteresis.

The SRE strategy not only eliminates the local de-wetting problem of perovskite ink, thus achieving uniform polycrystalline perovskite films at the decimeter level, but also imparts enhanced performance in electronic properties, stability, mechanical adhesion at the buried interface via modulating the NiOx surface features.

In their recent study, the researchers achieved high-performance PSCs with a stability of thousands of hours under various stressed conditions and outstanding photovoltaic performance. The power conversion efficiencies of PSCs were 23.4% and 21.3% for rigid and flexible devices, respectively.

Furthermore, due to the scalability of the SRE strategy to large-area configurations, the team assembled perovskite submodules of 156 × 156 mm2 with a remarkable efficiency of 18.6% along with negligible hysteresis and good stability.

"The SRE strategy provides a proof of concept for combining vacuum-fabricated charge transport layers with wet-processed perovskites and facilitates the stacking engineering of large-scale, uniform thin films for the development of efficient and stable perovskite modules," said Prof. LIU.