Scientists from the Korea Institute of Machinery and Materials, Kyungpook National University, Sungkyunkwan University, Sejong University and Yonsei University in Korea, in collaboration with Uppsala University in Sweden, Imperial College London and National Renewable Energy Laboratory in the U.S, recently devised a way to sustainably collect pollutants secreted from PSCs without sacrificing the panel itself. Using this new approach, the scientists were able to safely recycle 99.7% of lead in their samples.

In the study describing their work, the researchers explain that they're not the first to attempt to tackle this issue, but that previous approaches to adsorbing lead have been limited by the number of naturally occurring lead solvents.

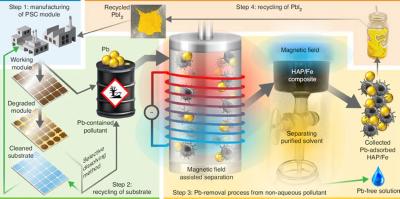

Similar to an air filter, the authors explain that their goal is to collect the polluted material from solar panels, pass it through their adsorption process, and return a lead iodide to the manufacturers to be reused ' thus creating a sustainable, (mostly) closed processing loop.

In order to do this, the team engineered a special way to adsorb lead from the perovskite solar cells. Importantly, this process is different from absorbing the lead, which would imply that the entire toxic substance was somehow enveloped. Instead, this adsorption process works by clinging to the surface of the lead and separating it through magnetic fields.

Their process starts at the solar cell manufacturing plant with panels that are slowly degraded over time from lead. This lead is then melted off the panels using a dissolving process and taken to a specialized adsorption chamber that uses a magnetic field to separate lead ions from other pollutants.

Once separated, the cleaned lead can then be recycled back to the manufacturers in the form of lead iodide to be used in the creation of more solar cells. The authors write that the incorporation of iron into their adsorbent made the collection of lead even easier.

"[Our] recycled PbI2 is comparable in quality to commercial PbI2; thus, our study enables a zero-lead-emission route for future perovskite technologies," write the authors.

The researchers say that they were able to recycle nearly all lead passed through their adsorbents for a recycling yield of 99.7%. They were also able to meet Environmental Protection Agency guidelines for the level of lead permitted in a solution after their separating process.

Ultimately, the team writes, this study demonstrates the potentials of using economical, as well as bio- and environmentally friendly, adsorbents in heavy metal management.

"Our approach paves a way for [pervoskite solar cell] manufacturing with zero Pb emission and, by extension, provides the methodology for recycling and managing lead from waste devices to allay concerns on Pb-related environmental issues," the authors say.