Perovskites are materials that share a crystal structure similar to the mineral called perovskite, which consists of calcium titanium oxide (CaTiO3).

Depending on which atoms/molecules are used in the structure, perovskites can possess an impressive array of interesting properties including superconductivity, ferroelectricity, charge ordering, spin dependent transport and much more. Perovskites therefore hold exciting opportunities for physicists, chemists and material scientists.

Quantum dots (QDs), sometimes referred to as semiconducting nanocrystals (NCs), are miniscule particles of a semiconducting material with diameters in the range of 2-10 nanometers (10-50 atoms). Quantum dots have properties labeled as intermediate between bulk semiconductors and discrete atoms or molecules. Their optoelectronic properties change as a function of both size and shape. QDs demonstrate optical and electronic properties different from those of larger particles. In fact, QDs tend to exhibit quantum size effects in their optical and electronic properties, like tunable and efficient photoluminescence (PL), with narrow emission and photochemical stability. This is why QDs have been incorporated as active elements in a wide variety of devices and applications, some of which are already commercially available, such as QD-based displays.

Perovskite quantum dots (PQDs) are a class of quantum dots based on perovskite materials. While these are relatively new, they have already been shown to have properties matching or surpassing those of the metal chalcogenide QDs: they are more tolerant to defects and have excellent photoluminescence quantum yields and high colour purity. Such attractive properties are extremely suited for electronic and optoelectronic applications and so perovskite quantum dots have significant potential for real world applications, some of which are already emerging, including LED displays and quantum dot solar cells.

Perovskite-Info launches a new edition of its Perovskite for Displays Market Report

Perovskite-Info is proud to announce an update to our Perovskite for the Display Industry Market Report. This market report, brought to you by the world's leading perovskite and OLED industry experts, is a comprehensive guide to next-generation perovskite-based solutions for the display industry that enable efficient, low cost and high-quality display devices. The report is now updated to July 2024, with all the latest commercial and research activity - including 9 new research papers, new company, new brochures, and commercial updates and more!

Reading this report, you'll learn all about:

- Perovskite materials and their properties

- Perovskite applications in the display industry

- Perovskite QDs for color conversion

- Prominent perovskite display related research activities

The report also provides a list of perovskite display companies, datasheets and brochures of pQD film solutions, an introduction to perovskite materials and processes, an introduction to emerging display technologies and more.

Helio and Haylo Ventures to target micro displays with perovskite platform

A few months ago, Helio Display Materials, a developer of perovskite-based color conversion materials for displays, announced that it entered into a strategic partnership with Haylo Ventures, a venture operator specializing in accelerating the commercialization of deep tech.

This collaboration targets micro displays for AR/VR headsets, signifying a pivotal shift in Helio's strategic direction.

Researchers develop high-efficiency pure red light-emitting diodes through surface modification of perovskite QDs

Researchers from Korea's Daegu Gyeongbuk Institute of Science and Technology (DGIST), Ulsan National Institute of Science and Technology (UNIST) and Institute for Basic Science (IBS) recently developed high-performance, skin-attachable perovskite pure red light-emitting devices to create various forms of wearable displays.

The team developed these devices through selective surface modification of perovskite quantum dots, expecting their future use in diverse wearable products. As traditional red perovskite materials were unsuitable for high-performance wearable displays due to their low stability and electrical properties, the research team created pure red light-emitting devices through the simple surface modification of the perovskite light-emitting layers, thus significantly improving their stability and electrical properties.

Researchers achieve 3D printing of luminescent perovskite quantum dot–polymer architectures

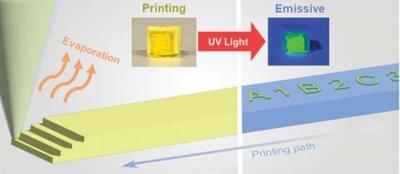

Researchers from Ulsan National Institute of Science and Technology (UNIST), Korea Electrotechnology Research Institute (KERI) and Sungkyunkwan University (SKKU) recently developed a straightforward and effective method for producing 3D architectures of perovskite quantum dot (PQD)-encapsulated high-performance composites (PQD-HPCs) through direct-ink writing (DIW).

Schematic of the direct-ink writing (DIW) approach of luminescent PQD–polymer architectures. Image from Advanced Functional Materials

Led by Professor Im Doo Jung from the Department of Mechanical Engineering at UNIST, the recent study introduced a cutting-edge one-stop perovskite quantum dot (PQD) additive manufacturing technology. This approach eliminates the need for heat treatment, allowing for the creation of complex 3D shapes with exceptional precision, including iconic landmarks like the Eiffel Tower.

Researchers create all-inorganic perovskite nanocrystalline glass doped with rare-earth ions

Researchers from China's Kunming University of Science and Technology and Southwest United Graduate School have doped rare-earth ions into borosilicate glass for the first time to induce the self-crystallization of CsPbBr3 QDs.

All-inorganic perovskite quantum dots (QDs) in glass materials, specifically CsPbX3 (X = Cl, Br, I), have potential as next-generation fluorescent materials due to their impressive luminous performance and stability. However, the crystallization process of quantum dots within the glass presents a challenge, leading to uneven crystallinity and subsequent reductions in light efficiency, thereby affecting practical applications. In glass ceramics doped with rare-earth oxides, the introduction of rare-earth ions as nucleating agents can promote the self-precipitation of nanocrystalline crystals within the glass.

Perovskites’ bright future in the MicroLED industry

Micro-LED (also known as mLED or µLED) is a display technology based on miniature LED devices that are used to directly create color pixels. Micro-LED displays are highly promising and have the potential to create efficient and great looking flexible displays, which could challenge even the most impressive high-end OLED displays. Micro LEDs are attracting significant attention as next-generation displays owing to their desirable characteristics such as low power consumption, high contrast ratio, high brightness, fast response speed, and long life span.

Perovskite materials can benefit the MicroLED industry in two ways: as materials for color conversion (using perovskite-based QDs) and in perovskite-based LED emitters. Much R&D work is taking place on both these fronts, and interest seems to be growing.

Researchers use ligand-passivation engineering to achieve high performance indoor perovskite quantum dot photovoltaics

Researchers at Korea University, Kyungpook National University, Hanyang University, Dongguk University and Mississippi State University have used a novel ligand passivation strategy in perovskite quantum dots (PQDs) photovoltaics (PQDPVs) to enhance the carrier lifetime.

The advancement of perovskite photovoltaic (PePV) systems for harnessing indoor light energy has been accelerated by the advent of the Internet of Things (IoT). However, the commercialization of these systems is impeded by moisture instability and restricted carrier lifetimes. Perovskite quantum dots (PQDs) offer viable solutions for increasing stability despite the potential effects of their organic ligands on efficiency.

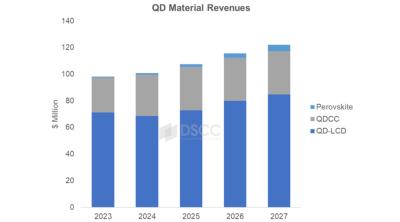

DSCC foresees revenue growth for QDs in the display market, perovskite QDs to start capturing market share

DSCC, a provider of display market research and consulting services, recently published its projections regarding revenues from QDs. According to DSCC, demand for QD materials in the display industry is growing, and the market will grow to $100 million in 2024. It will continue to grow and reach $122 million in 2027.

DSCC specifically predicts that perovskite materials will capture some market share. It explained that green perovskite is available but red perovskite is still under development, so it is often paired with a red phosphor. The technology is currently in the early stage of commercialization and the supply chain will take some time to build.

Researchers report annealing-free flexible perovskite quantum dot solar cells that use UV-sintered Ga-doped SnO2 electron transport layers

Researchers from Hanyang University, Nankai University and Kookmin University have developed a room-temperature-processed tin oxide (SnO2) ETL preparation method for flexible perovskite quantum dots (PQD) solar cells. Low-temperature ETL deposition methods are especially desirable for fabricating flexible solar cells on polymer substrates.

The process involves synthesizing highly crystalline SnO2 nanocrystals stabilized with organic ligands, spin-coating their dispersion, followed by UV irradiation. The energy level of SnO2 is controlled by doping gallium ions to reduce the energy level mismatch with the PQD.

Perovskite-Info launches a new edition of its Perovskite for Displays Market Report

Perovskite-Info is proud to announce an update to our Perovskite for the Display Industry Market Report. This market report, brought to you by the world's leading perovskite and OLED industry experts, is a comprehensive guide to next-generation perovskite-based solutions for the display industry that enable efficient, low cost and high-quality display devices. The report is now updated to February 2024, with all the latest commercial and research activity. This was a major version, with over 15 updates, new companies and new technologies covered.

Reading this report, you'll learn all about:

- Perovskite materials and their properties

- Perovskite applications in the display industry

- Perovskite QDs for color conversion

- Prominent perovskite display related research activities

The report also provides a list of perovskite display companies, datasheets and brochures of pQD film solutions, an introduction to perovskite materials and processes, an introduction to emerging display technologies and more.

Pagination

- Page 1

- Next page