Researches develop low-temperature processes to reduce silver use in tandem perovskite-silicon solar cells

Researchers from the Fraunhofer Institute for Solar Energy Systems (Fraunhofer ISE) and Oxford PV Germany have developed low temperature manufacturing processes for perovskite silicon tandem cells and heterojunction solar cells. The novel techniques are reportedly able to reduce silver consumption and avoid lead-containing soldering materials.

The scientists developed two different processes: front-side metallization at very low temperatures for full-size perovskite silicon tandem solar cells; and the interconnection to high-efficiency full-format demonstrator modules with an output power of more than 400 W.

Oxford PV announces new efficiency record

Oxford PV has announced 'a new world record for the efficiency of a commercial-sized solar cell'. The efficiency record was achieved on a commercial-sized ‘M4’ (258.15 cm2) solar cell. The cell is a 2T device made by depositing a perovskite thin-film cell onto a conventional silicon heterojunction cell.

The record-breaking solar cell converted 28.6% of the sun’s energy into electricity, as independently certified by Fraunhofer ISE. The solar cell was produced at Oxford PV’s integrated production line in Brandenburg an der Havel, Germany. The factory has commenced initial production of the company’s tandem solar cells for integration by solar module manufacturing partners and is ramping up to higher volumes. The site, operational since 2017, houses the world’s first volume manufacturing line for perovskite-on-silicon tandem solar cells.

"Katana" project to establish reliable measuring system for tandem solar cells

To pave the way for the industrial implementation of efficient perovskite-silicon PV modules, a reliable measuring system for tandem solar cells and modules must be established. Only then can objective comparisons between different cells and modules take place. In contrast to conventional silicon PV modules, however, the calibration is considerably more challenging.

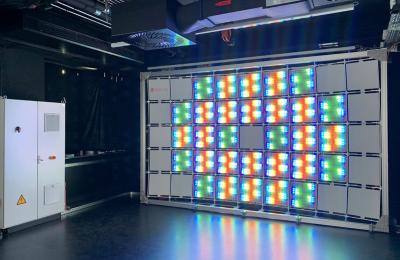

A project consortium, led by the Fraunhofer Institute for Solar Energy Systems ISE, is therefore developing methods for characterizing perovskite-based tandem modules in the "Katana" project, funded by the German Federal Ministry for Economic Affairs and Climate BMWK. The solar simulator specially built for this purpose by the company Wavelabs Solar Metrology Systems GmbH is now in use in the CalLab PV Modules of the research institute.

New project will utilize quantum computing to advance perovskite PV materials

A UK-based quantum software company called Phasecraft will lead a project modelling new perovskite-silicon materials for solar photovoltaics. The project, in collaboration with Oxford PV and scientists at University College London (UCL), is aimed to support the development of quantum computing to simulate “currently intractable problems” in PV materials modelling, according to a recent statement.

Not many details were given regarding the new project, which received an award from UK Research and Innovation’s Commercializing Quantum Technologies Challenge. It was, however, said that it will set out to develop a modelling capability that is tailored to the real-world needs of the PV industry.

Researchers examine the environmental performance of perovskite-on-silicon tandem solar cells

A team of scientists from Technische Universität Berlin, Oxford PV Germany, German Philipps-Universität Marburg, Helmholtz Zentrum Berlin (HZB) and Oxford PV UK has, for the first time, assessed the environmental performance of industrially produced perovskite-on-silicon PV modules. Understanding the environmental impact of solar PV modules across their entire lifecycle is essential for the design of more sustainable solar energy systems. However, lifecycle assessment of perovskite-on-silicon PV modules has so far relied heavily on data from laboratory and test facilities rather than manufacturers.

The researchers conducted a comprehensive lifecycle assessment of a perovskite-on-silicon module across a number of categories including global warming potential, water consumption, human and marine toxicity, and metals usage. They assessed the materials and energy input for a module’s ‘cradle to gate’ lifecycle, covering all materials and energy input for wafer production, manufacture of the perovskite cell, and module production. The researchers then weighed up the environmental impact of the tandem module against the electricity generated over its lifetime.

Pagination

- Previous page

- Page 2

- Next page