Researchers show how inner doping of CNTs with perovskites can yield ultralow power transistors

As silicon-based transistors approach their limits, researchers are exploring alternative materials to continue progress in semiconductor technology. Carbon nanotubes (CNTs) are considered promising candidates for next-generation electronics due to their exceptional electrical properties and nanoscale dimensions. Yet, the challenge of precisely controlling the electronic characteristics of CNTs has hindered their widespread adoption in practical applications.

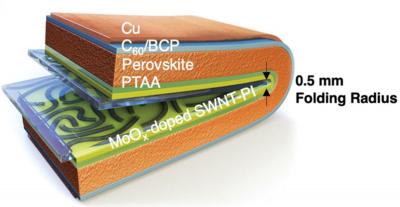

Researchers at China's Peking University, Zhejiang University and Chinese Academy of Science (CAS) have developed an inner doping method by filling CNTs with 1D halide perovskites to form a coaxial heterojunction, which enables a stable n-type field-effect transistor for constructing complementary metal–oxide–semiconductor electronics.