SLAC team reveals unusual atomic motion that could help explain the efficiency of perovskite solar cells

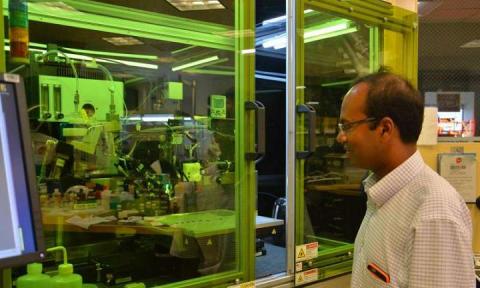

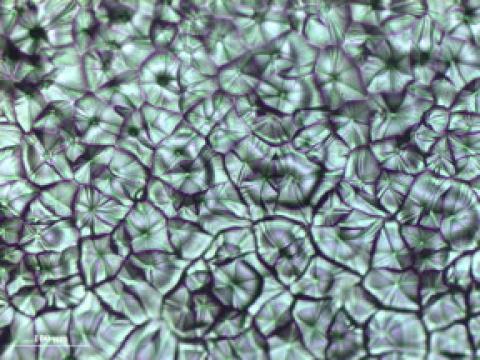

Researchers at the Department of Energy's SLAC National Accelerator Laboratory have used a powerful "electron camera" to establish that light whirls atoms around in perovskites, potentially explaining the high efficiency of perovskite-based solar cell materials and providing clues for making better ones.

The scientists recorded movies that show that certain atoms in a perovskite respond to light within trillionths of a second in a very unusual manner. They explain that this may facilitate the transport of electric charges through the material and boost its efficiency.