This is a sponsored post by MBRAUN

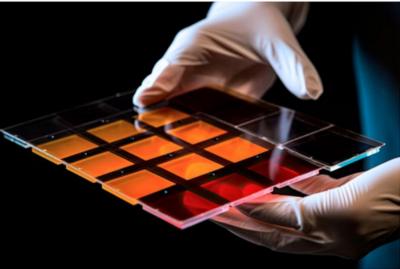

In the quest for cleaner, more efficient energy sources, perovskite solar cells have proven to be a promising prospect. Their exceptional efficiency, low-cost production and versatility make them a promising candidate for revolutionizing the renewable energy. However, the road to mass adoption faces hurdles, one of which is the need for precise and efficient manufacturing processes. Here's where vacuum evaporation tools shine as indispensable assets in the production of perovskite solar cells.

Precision Engineering for Optimal Performance

At the heart of perovskite solar cell fabrication lies the deposition of thin films with utmost precision under highly controlled conditions. MBRAUN evaporation tools from the PEROvap series offer unparalleled control over the deposition process, ensuring the uniformity and consistency essential to maximize solar cell efficiency. Addressing the volatility of most used Perovskite materials PEROvap systems are designed to control the temperature of the chamber, the substrate holder, the sources and the quartz crystals precisely from -40°C up to room. This avoids unwanted re-evaporation of already deposited materials and stabilizes the overall evaporation process. By vaporizing the material under vacuum conditions and depositing it onto the substrate, PEROvaps also eliminate impurities and defects that could affect performance, resulting in high-quality perovskite films with superior optoelectronic properties.

Learn more about the vacuum coating solutions from MBRAUN

Tailor-made Solutions for Diverse Applications

Perovskite solar cells hold immense potential beyond traditional silicon-based photovoltaics. Their flexibility allows for applications in curved surfaces, building-integrated photovoltaics, and even wearable electronics. The MBRAUN portfolio of evaporators empower manufacturers to explore these diverse applications by offering customizable configurations starting from multiple different source types, heating/cooling functionalities, automated substrate transfer up to pre-programmed reference processes which allow the user to start his research directly after the system has been delivered. Whether it's tuning the thickness of the perovskite layer or depositing multi-layered structures, MBRAUN evaporators provide the flexibility needed to meet the demands of various applications while maintaining efficiency and reliability.

Efficiency and Sustainability Hand in Hand

In the pursuit of sustainable energy solutions, efficiency is paramount not only in the performance of solar cells but also in the manufacturing processes. MBRAUN evaporation tools excel in this regard by minimizing material waste and energy consumption. Their high deposition rates and low process temperatures reduce energy requirements, while the ability to deposit thin films with atomic-level precision ensures minimal material usage. This not only translates to cost savings but also aligns with the sustainability goals driving the renewable energy revolution.

Green Energy Revolution with MBRAUN

Pushing the Boundaries of Innovation

The field of perovskite research is developing rapidly, continuously pushing the boundaries of efficiency and stability. Vacuum evaporation systems play a central role in this innovation cycle by facilitating experimentation and optimization. Researchers can easily explore novel materials, deposition techniques and device architectures, accelerating the pace of discovery and bringing us closer to commercially viable perovskite-based technologies.

Conclusion

As we strive towards a sustainable future powered by renewable energy, the role of vacuum evaporation tools in perovskite manufacturing cannot be overstated. Their precision, versatility, efficiency, and sustainability make them indispensable assets in the quest to unlock the full potential of perovskite solar cells. By harnessing the power of vacuum evaporation, we pave the way for a brighter, cleaner tomorrow.