The following is a sponsored post by Toray Engineering

In an article dated Oct 17, 2022, Toray Engineering introduced its slot-die coating technology, as well as other technologies that can be utilized for perovskite layer deposition for large-scaled production.

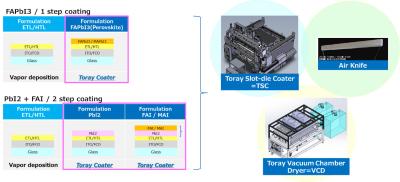

This article will describe two processes to formulate Perovskite layers using such technologies, using Toray Engineering’s manufacturing equipment. One of the processes is a 1-step coating method that applies FAPBI3 coating to formulate a power-generation layer. The other process is a 2-step coating method that double coats PBI2 and FAI to formulate a power-generation layer. For both processes, by combining its technologies in slot-die, vacuum dryer, and air knife, Perovskite layers can be formulated on large-scale glass surfaces.

For the 1-step coating, FAPBI3 is coated on the bare glass using slot-die, which is immediately followed by air-knife drying to facilitate the drying process. Then the coated glass is vacuum dried and baked as shown on the diagram and photos below. With Toray Engineering’s extensive experience with large-size slot-die coating, cultivated through many years of accumulated expertise in the display industry, deposition of Perovskite layers on over-meter glass (the glass in the photo is 1100×1300mm)has already been achieved in demo level. In addition, the Company is collaborating with material makers to validate and enhance the process; in this demo, materials by Kyocera Document Solutions are used.

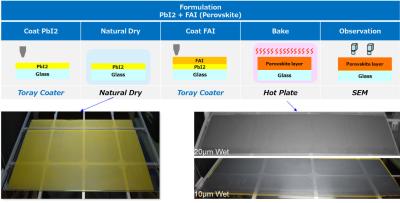

For the 2-step coating, PbI2 is coated on the bare glass and dried naturally, and then, FAI is coated on top of this first layer and baked in the hot plate. The wet film thickness of FAI can be adjusted to enhance the quality of the Perovskite layer. Such easily adjustable wet film thickness in this 2-step coating makes it possible to pinpoint a more optimal process.

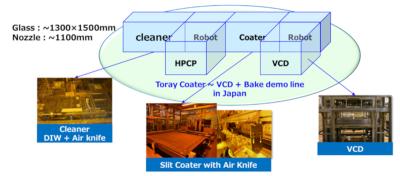

The coating test for these 2 processes were carried out using Toray Engineering’s demo equipment at its lab in Shiga, Japan. As the diagram below shows, the demo equipment consists of a cleaner slot-die coater, VCD and hot plate that can transfer and process the substrate over 1 meter. For any Perovskite solar cell manufacturers looking into scaling up their production into larger size panels, Toray Engineering is open to collaboration with such manufacturers to establish the processes using its demo equipment.