Researchers develop a thin and flexible perovskite-based scanner for fingerprints

Researchers from TNO at Holst Centre, Solliance and TU/e have jointly developed a thin and flexible perovskite-based scanner for fingerprints.

Low-resolution image-sensor arrays have been demonstrated in the past, but the high-resolution, high pixel-count image sensors suitable for commercial applications have not yet been truly achieved. The thin and flexible scanner in this new work is based on metal-halide perovskites (MHPs). Gerwin Gelinck, Chief Technology Officer TNO at Holst Centre, elaborates on the new study: 'Perovskites are marvelous materials! For the first time we show that these materials are also very good for light imaging and sensing applications. When combined with display-like transistors, we made a scanner that can capture high-resolution color images as well as biometric fingerprinting'.

Solliance reports two new records for 4T perovskite tandems

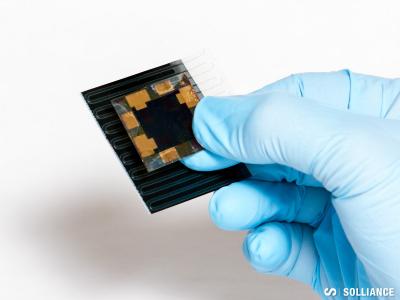

Solliance recently announced that a collaboration with the M2N group of René Janssen at University of Technology Eindhoven has resulted in two world-records for 4T perovskite tandems.

The partners reported that they further optimized the wide-bandgap (1.69eV) perovskite cells with high near-infrared transparency for 4T tandem applications. The perovskite cell has reached a stabilized efficiency of 17.8% during 5-min maximum-power-point tracking. In combination with the Panasonic silicon bottom cell, a new world-record 4T perovskite/Si tandem efficiency of 29.2% was realized.

Solliance partners reach new efficiency record with four terminal tandem configurations

Solliance partners TNO, imec/EnergyVille and the Eindhoven University of Technology, have reported a 18.6% efficient highly near infrared transparent perovskite solar cell. When combined in a four terminal tandem configuration with an efficient Panasonic crystalline silicon (c-Si) cell or with a Miasolé flexible CIGS cell, the configuration delivered new record power conversion efficiencies of 28.7% and 27.0%, respectively.

The researchers explained that four terminal tandems allow to build on experience and practices already available in the industry. In addition, four terminal perovskite/c-Si tandems can be applied broadly and are, for example, very beneficial in combination with bifacial c-Si solar cells which, depending on the actual albedo, can readily achieve a total power generation density as high as 320 W/m2.

Flexible semi-transparent tandem perovskite/CIGS solar cell with 26.5% efficiency reported by Solliance and MiaSolé

Solliance and U.S-based MiaSolé announced a new record - power conversion efficiency of 26.5% on a tandem solar cell that combined a top rigid semi-transparent perovskite solar cell with a bottom flexible copper indium gallium selenide (CIGS) cell.

This impressive efficiency was achieved by optimizing the bandgap and the efficiency of both the rigid semi-transparent perovskite top cell and the flexible CIGS bottom cell. The CIGS was roll to roll produced on steel foil, with a power conversion efficiency of 20.0%.

International consortium announces 25% efficiency for perovskite CIGS solar cell

Scientists from Hasselt University, imec, VITO, EnergyVille and international partners within the PERCISTAND consortium have announced that they achieved an energy efficiency of 25% with a thin-film solar cell.

Bart Vermang, coordinator within the PERCISTAND consortium, describes the development of thin-film solar cells as 'Pioneering'. The consortium, which partly consists of the collaborations within EnergyVille and Solliance, has succeeded in achieving a record energy efficiency with thin film solar cells. 'We've achieved an energy efficiency of 25 percent for the first time, which is just as much energy as a traditional solar cell can generate on a day-to-day basis. And we haven't yet reached the upper limit of our thin-film solar cells.'

Pagination

- Previous page

- Page 2

- Next page