Scaled perovskite solar modules pass three critical stability tests

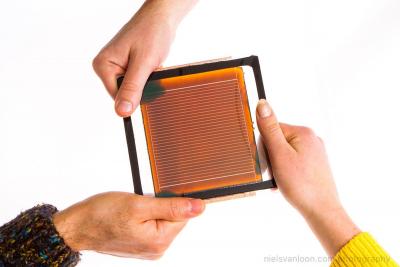

In what is said to be a "major milestone toward commercialization", Solliance partners TNO, imec and the Eindhoven University of Technology demonstrated encapsulated perovskite solar modules fabricated using industrial processes that withstand three established lifetime tests, i.e. the light soak test, the damp-heat test and the thermal cycling test. It is for the first time this milestone is passed with scaled perovskite solar modules prepared by research organizations.

The efficiency and versatility of perovskite solar modules has generated a lot of interest in this novel solar energy technology. However, concerns have been raised about the stability of perovskite solar modules since the early devices, reported a decade ago, were only stable for minutes. By passing three rigorous aging tests, Solliance and its industrial partners take a major step towards commercialization of this novel solar technology.

The new EPKI initiative will push forward perovskite technologies

For the purpose of decarbonizing the energy-mix, which is becoming a priority challenge for European countries among others, European universities, research institutes and industries involved in the development of perovskite technologies have agreed on the creation of a collaborative platform: the EPKI.

This initiative is dedicated to gathering all significant parties working in this field and is pursuing the following objectives:

- Raise the awareness on perovskite based photovoltaics by conveying a common vision through the editing of a common European perovskite whitepaper,

- Support and initiate next generation PV industrial initiatives,

- Facilitate joint-research programs and synergies among universities, institutes and companies.

Netherlands’ ECN reaches 30.2% efficiency for bifacial tandem cell based on perovskite

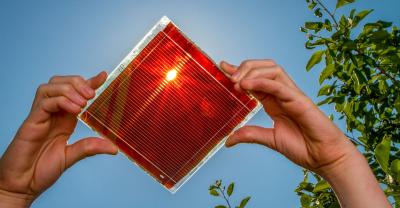

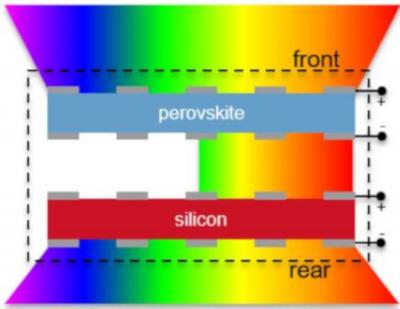

Researchers at the Energy Research Center of the Netherlands (ECN) have developed a bifacial tandem solar cell with a conversion efficiency of 30.2%. The new cell device ' created with Dutch consortium Solliance ' was made by applying a newly developed perovskite cell on top of an industrial bifacial crystalline silicon version.

This approach, according to the scientists, enables a significantly higher power conversion efficiency as one cell is optimized for high energy photons, and the other low energy particles. 'The tandem device proposed here uses a four-terminal configuration, thus having separate circuits for the top and bottom cells that allow for dynamic fine tuning and optimization of the energy yield,' the creators of the cell wrote. The cell is also said to be better able to capture light on its front and rear sides by responding to the variability of incident light through its electronic design.

TNO and TU/e develop thermally stable perovskite solar cells

Solliance Solar Research has announced a major accomplishment in the thermal stability of perovskite technology. The thermal stability was tested over a period of 3.000 hours. After this thermal stress test, the cell performance showed 93% of the initial performance.

Mehrdad Najafi, researcher at Solliance Solar Research, who will be presenting the work at the EU PVSEC in Belgium on September 27th, states: "Perovskite solar cells have attracted great attention due to their high power conversion efficiency Demonstrated stability and scale-ability, two very important topics within the Solliance collaboration, are the next steps towards successful commercialization of this technology. Our recent results show that it is possible to achieve stable perovskite solar cells upon prolonged exposure to thermal stress. After a further full-stack optimization and the introduction of a metal oxide layer by means of Atomic Layer Deposition (ALD), the thermal stability improved drastically compared with our previous reference: instead of losing over 50% of its performance after 100 hours at 85oC, we now demonstrate only 7% of performance loss after 3.000 hours at 85oC. This is an important stepping stone towards full IEC compliance".

Perovskite/CIGS tandem cell reaches 24.6% efficiency

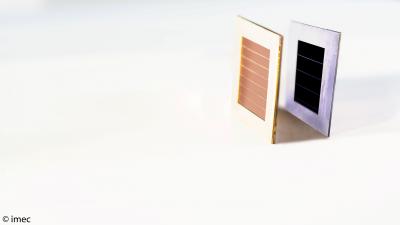

imec, the world-leading research and innovation hub, recently presented an impressive thin-film tandem solar cell at the EU PVSEC conference. The cell consists of a top perovskite cell developed by imec within the partnerships of EnergyVille and Solliance, and a bottom CIGS cell from the Centre for Solar Energy and Hydrogen Research (ZSW, Stuttgart, Germany). The tandem cell resulting from this collaboration achieves a record efficiency of 24.6%.

The perovskite top cell in the tandem uses light in the visible part of the solar spectrum, while the light in the near-IR spectrum that passes through the perovskite cell is harvested by the underlying CIGS cell. In this way, the tandem cell significantly outperforms the stand-alone perovskite and CIGS cells. Moreover, both perovskite and CIGS cells are thin-film solar cells, paving the way to high efficiency flexible solar cells and building integrated photovoltaic (BIPV) solutions.

Pagination

- Previous page

- Page 3

- Next page