Researchers develop thin, flexible quasi-2D PSCs and demonstrate them in energy-autonomous drones

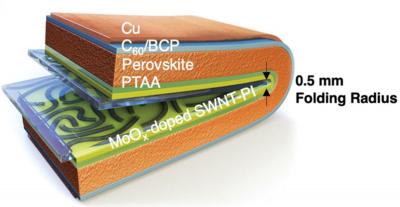

Researchers from Austria's Johannes Kepler University Linz have developed lightweight, thin (<2.5 μm), flexible and transparent-conductive-oxide-free quasi 2D perovskite solar cells by incorporating alpha-methylbenzyl ammonium iodide into the photoactive perovskite layer.

The team fabricated the devices directly on an ultrathin polymer foil coated with an alumina barrier layer to ensure environmental and mechanical stability without compromising weight and flexibility.