Researchers achieve temperature-dependent phase stable hybrid halide perovskite films by CVD

Researchers from South-Africa's University of the Western Cape, University of Missouri and Argonne National Laboratory have developed a new way of enhancing the stability and performance of perovskites.

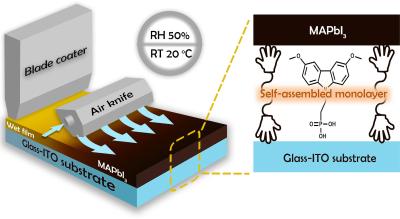

Missouri University professor Suchismita (Suchi) Guha, the lead author of the study, and her collaborators improved the methods for making lead halide perovskites. Previous techniques for making these thin-film perovskites required liquid processing using solvents, which rendered the films susceptible to degradation when exposed to air. Additionally, with prior manufacturing processes, one of its molecules undergoes a change to its structure, causing performance limitations in real-world operating conditions.

With the new technique, the researchers were able to prevent the change, holding the affected molecule in a stable structure throughout a large temperature range. Additionally, the new technique rendered the perovskite air stable, making it appropriate for a potential solar cell.