Perovskite Solar

What are perovskite?

Perovskites are a class of materials that share a similar structure, which display a myriad of exciting properties like superconductivity, magnetoresistance and more. These easily synthesized materials are considered the future of solar cells, as their distinctive structure makes them perfect for enabling low-cost, efficient photovoltaics. They are also predicted to play a role in next-gen electric vehicle batteries, sensors, lasers and much more.

How does the PV market look today?

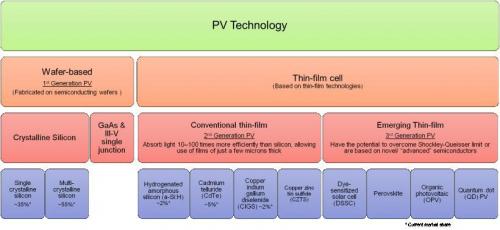

In general, Photovoltaic (PV) technologies can be viewed as divided into two main categories: wafer-based PV (also called 1st generation PVs) and thin-film cell PVs. Traditional crystalline silicon (c-Si) cells (both single crystalline silicon and multi-crystalline silicon) and gallium arsenide (GaAs) cells belong to the wafer-based PVs, with c-Si cells dominating the current PV market (about 90% market share) and GaAs exhibiting the highest efficiency.

Thin-film cells normally absorb light more efficiently than silicon, allowing the use of extremely thin films. Cadmium telluride (CdTe) technology has been successfully commercialized, with more than 20% cell efficiency and 17.5% module efficiency record and such cells currently hold about 5% of the total market. Other commercial thin-film technologies include hydrogenated amorphous silicon (a-Si:H) and copper indium gallium (di)selenide (CIGS) cells, taking approximately 2% market share each today. Copper zinc tin sulphide technology has been under R&D for years and will probably require some time until actual commercialization.

What is a perovskite solar cell?

An emerging thin-film PV class is being formed, also called 3rd generation PVs, which refers to PVs using technologies that have the potential to overcome current efficiency and performance limits or are based on novel materials. This 3rd generation of PVs includes DSSC, organic photovoltaic (OPV), quantum dot (QD) PV and perovskite PV.

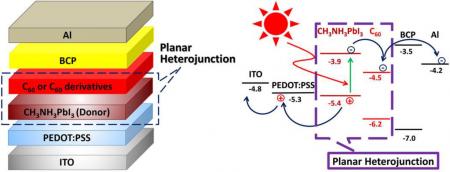

A perovskite solar cell is a type of solar cell which includes a perovskite structured compound, most commonly a hybrid organic-inorganic lead or tin halide-based material, as the light-harvesting active layer. Perovskite materials such as methylammonium lead halides are cheap to produce and relatively simple to manufacture. Perovskites possess intrinsic properties like broad absorption spectrum, fast charge separation, long transport distance of electrons and holes, long carrier separation lifetime, and more, that make them very promising materials for solid-state solar cells.

Perovskite solar cells are, without a doubt, the rising star in the field of photovoltaics. They are causing excitement within the solar power industry with their ability to absorb light across almost all visible wavelengths, exceptional power conversion efficiencies already exceeding 20% in the lab, and relative ease of fabrication. Perovskite solar cells still face several challenge, but much work is put into facing them and some companies, are already talking about commercializing them in the near future.

What are the advantages of Perovskite solar cells?

Put simply, perovskite solar cells aim to increase the efficiency and lower the cost of solar energy. Perovskite PVs indeed hold promise for high efficiencies, as well as low potential material & reduced processing costs. A big advantage perovskite PVs have over conventional solar technology is that they can react to various different wavelengths of light, which lets them convert more of the sunlight that reaches them into electricity.

Moreover, they offer flexibility, semi-transparency, tailored form factors, light-weight and more. Naturally, electronics designers and researchers are certain that such characteristics will open up many more applications for solar cells.

What is holding perovskite PVs back?

Despite its great potential, perovskite solar cell technology is still in the early stages of commercialization compared with other mature solar technologies as there are a number of concerns remaining.

One problem is their overall cost (for several reasons, mainly since currently the most common electrode material in perovskite solar cells is gold), and another is that cheaper perovskite solar cells have a short lifespan. Perovskite PVs also deteriorate rapidly in the presence of moisture and the decay products attack metal electrodes. Heavy encapsulation to protect perovskite can add to the cell cost and weight. Scaling up is another issue - reported high efficiency ratings have been achieved using small cells, which is great for lab testing, but too small to be used in an actual solar panel.

A major issue is toxicity - a substance called PbI is one of the breakdown products of perovskite. This is known to be toxic and there are concerns that it may be carcinogenic (although this is still an unproven point). Also, many perovskite cells use lead, a massive pollutant. Researchers are constantly seeking substitutions, and have already made working cells using tin instead. (with efficiency at only 6%, but improvements will surely follow).

What’s next?

While major challenges indeed exist, perovskite solar cells are still touted as the PV technology of the future, and much development work and research are put into making this a reality. Scientists and companies are working towards increasing efficiency and stability, prolonging lifetime and replacing toxic materials with safer ones. Researchers are also looking at the benefits of combining perovskites with other technologies, like silicon for example, to create what is referred to as “tandem cells”.

Commercial activity in the field of perovskite PV

In September 2015, Australia-based organic PV and perovskite solar cell (PSC) developer Dyesol declared a major breakthrough in perovskite stability for solar applications. Dyesol claims to have made a significant breakthrough on small perovskite solar cells, with “meaningful numbers” of 10% efficient strip cells exhibiting less than 10% relative degradation when exposed to continuous light soaking for over 1000 hours. Dyesol was also awarded a $0.5 million grant from the Australian Renewable Energy Agency (ARENA) to commercialize an innovative, very high efficiency perovskite solar cell.

Also in 2015, Saule Technologies signed an investment deal with Hideo Sawada, a Japanese investment company. Saule aims to combine perovskite solar cells with other currently available products, and this investment agreement came only a year after the company was launched.

In October 2020, Saule launched sunbreaker lamellas equipped with perovskite solar cells. The product is planned to soon be marketed across across Europe and potentially go global after that.

In August 2020, reports out of China suggested that a perovskite photovoltaic cell production line has gone into production in Quzhou, east China's Zhejiang Province. The 40-hectare factory was reportedly funded by Microquanta Semiconductor and expected to produce more than 200,000 square meters of photovoltaic glass before the end of 2020.

In September 2020, Oxford PV's Professor Henry Snaith stated that the Company's perovskite-based solar cells are scheduled to go on sale next year, probably by mid 2021. These will be perovskite solar cells integrated with standard silicon solar cells.

Researchers report photo-ferroelectric perovskite interfaces as a way to boost VOC in perovskite solar cells

Interface engineering plays a significant role in the constant improvement in the performance of perovskite photovoltaics, but such devices still suffer from several issues, including unavoidable open circuit voltage (VOC) losses. Now, an international team of researchers from Università Degli Studi Di Pavia, King Abdullah University of Science and Technology (KAUST), Chinese Academy of Sciences (CAS), University of Cambridge, Istituto Italiano di Tecnologia (IIT), Slovak Academy of Sciences and Imperial College London have proposed a different approach by creating a photo-ferroelectric perovskite interface.

Graphical representation of the 2D/3D/2D perovskite heterostructure. Image from: Nature Communications

By engineering an ultrathin ferroelectric two-dimensional perovskite (2D) which sandwiches a perovskite bulk, the scientists exploited the electric field generated by external polarization in the 2D layer to enhance charge separation and minimize interfacial recombination. As a result, they observed a net gain in the device VOC reaching 1.21 V, the highest value reported to date for highly efficient perovskite PVs, leading to a champion efficiency of 24%.

Halide Perovskite solar cells are shown to be ideal devices for in-sensor reservoir computing

As an increasing amount of multimodal sensors are used in intelligent electronics, energy expenditure gets more massive. Consequently, researchers aim to develop efficient computing paradigms or integrate energy harvesting from ambient sources. Halide perovskites possess unique photophysics and coupled ionic-electronic dynamics that actualize memory devices for brain-inspired computing. Synergizing the computing capability with their conventional light harvesting efficacy could address this issue.

Researchers from Singapore's Nanyang Technological University and Hong Kong's City University of Hong Kong recently examined the use of halide perovskite photovoltaics for in-sensor reservoir computing (RC).

Researchers use a self-assembled monolayer to fabricate 2D Ruddlesden-Popper perovskite solar cells with an efficiency exceeding 19 %

Two-dimensional Ruddlesden-Popper (2DRP) phase perovskites have excellent long-term environmental and structure stability. However, the efficiency of 2DRP perovskite solar cells (PSCs) still lags behind that of their 3D counterparts due to the large exciton binding energy between the large-volume organic spacer and the inorganic plate compared to their 3D analogs.

To address this issue, researchers from China's Northwestern Polytechnical University and Xijing University have used a thin layer of self-assembled monolayer material between the transporting layer and the perovskite film for efficient and stable 2DRP-based PSCs.

RenShine completes 1.2 MW perovskite distributed power station and connects it to the grid

Reports suggest that RenShine Solar has completed the construction of its 1.2 MW perovskite rooftop distributed power station. The plant is reportedly generating power and was connected to the grid on September 29.

The company says the plant’s power generation exceeded 3,000 kWh/day on its first day.

SolaEon Technology to launch 200MW + 1GW perovskite cell production lines

It was reported that SolaEon Technology, a Chinese manufacturer of next-gen solar cells with a focus on perovskite-based PV, recently signed an investment contract with the local government of Xuzhou City, China, as one of fifty-six contracts signed at the 27th Xuzhou Trade and Investment Fair.

SolaEon plans to invest about 1.2 billion yuan (almost USD$170 million) in the perovskite solar cell production base in the High-Tech Zone. Upon completion of the production lines with an annual capacity of 200MW and 1GW of perovskite cells, the production value is expected to reach 2 billion yuan (approximately USD$283 million) per year.

Researchers examine the influence of interfacial roughness on slot-die coatings for scaling-up perovskite solar cells

Slot-die coating (SDC) technology is a potential approach to mass produce large-area, high-performance perovskite solar cells (PSCs) at low cost. However, when the interface in contact with the perovskite ink has low wettability, the SDC cannot form a uniform pinhole-free perovskite film, which reduces the performance of the PSC.

Optimizing Slot-Die Coating for Commercial Solar Cell Production. Image credit: InfinityPV

Researchers from Korea's Jeonbuk National University have examined the correlation between interfacial roughness, wettability, and the overall efficiency of perovskite solar cells produced using slot-die-coating. This work offers a comprehensive understanding of how modifying the roughness of the hole transport layer (HTL) can improve the quality of perovskite films, enhance charge transport, and ultimately lead to high-efficiency perovskite solar cells with long-term stability.

Passivators based on lead carbanion yield inverted PSCs with 25.16% efficiency

Researchers from NingboTech University, Hunan Institute of Engineering, Hangna Nanofabrication Equipment Co. and University Malaysia Sabah have developed an inverted perovskite solar cell with an interface passivator based on lead carbanion (Pb–C–), that reportedly achieved the highest open-circuit voltage ever recorded for an inverted perovskite PV device. The lead carbanion layer was responsible for reducing defects at the interface between the perovskite layer and the electron transport layer.

Inverted perovskite cells, or “p-i-n” cells, have the hole-selective contact p at the bottom of intrinsic perovskite layer i with electron transport layer n at the top. Conventional halide perovskite cells have the same structure but reversed – a “n-i-p” layout. In a n-i-p architecture, the solar cell is illuminated through the electron-transport layer (ETL) side; in the p-i-n structure, it is illuminated through the hole‐transport layer (HTL) surface. Inverted perovskite solar cells are known for their impressive stability but have been held back by relatively low efficiencies. This issue mainly arises at the point where the perovskite layer meets the electron transport layer, causing energy loss instead of being converted into useful power, primarily caused by carrier recombination, especially at the interface between perovskite and the electron transport layer.

Researchers develop a novel strategy for increasing the efficiency of PSCs using FTO transparent conducting layers modified by atmospheric pressure plasma treatment on glass substrates

Researchers from Chungnam National University and Russian Academy of Sciences have reported a method to increase the efficiency of perovskite solar cells (PSCs) by modifying the surface of a fluorine-doped indium tin oxide (FTO) substrate using an atmospheric pressure plasma treatment.

The surface modification of the FTO film involved several challenges, such as control of the blocking layer uniformity, removal of pinholes, and deposition of a dense layer. This strategy allows the suppression of charge recombination at the interface between the FTO substrate and hole conductor.

DOE names recipients of SETO grants for R&D projects that focus on innovative ideas in photovoltaics

The U.S. Department of Energy (DOE) Solar Energy Technologies Office (SETO) Small Innovative Projects in Solar (SIPS) 2024 funding program provides $5.4 million for seedling R&D projects that focus on innovative and novel ideas in photovoltaics (PV) and concentrating solar-thermal power (CSP) and are riskier than research ideas based on established technologies.

The 16 selected projects were recently announced, among them were 5 perovskite-related projects.

New ligand exchange process enables improved perovskite quantum dots for efficient and stable solar cells

Researchers from Korea's Daegu Gyeongbuk Institute of Science and Technology (DGIST), Gyeongsang National University (GNU) and Kookmin University have developed a method to improve both the performance and the stability of solar cells using perovskite quantum dots. They developed longer-lasting solar cells by addressing the issue of distortions on the surface of quantum dots, which deteriorate the performance of solar cells.

A schematic diagram of bilateral ligand bonding on the surface of perovskite quantum dots. Image credit: Chemical Engineering Journal

Perovskite quantum dots can have excellent light-to-electricity conversion capabilities and are easy to mass-produce. However, according to the research team, in order to utilize them in solar cells, the ligands attached to the quantum dot surface must be replaced. This process often leads to distortions of the quantum dot surface, resembling crumpled paper, which results in decreased performance and shorter lifespans for the solar cells. To address this issue, the team adopted short ligands that securely hold the quantum dots from both sides, effectively uncrumpling the distorted surface. The ligands help restore the distorted lattice structure, smoothing the crumpled surface of the quantum dots. This significantly reduces surface defects, enabling the solar cells to operate more efficiently and extending their lifespan. Consequently, the power conversion efficiency of the solar cells increased from 13.6% to 15.3%, demonstrating stability by maintaining 83% of their performance for 15 days.

Pagination

- Previous page

- Page 2

- Next page