Energy Materials Corporation (EMC) has stated its plans for roll-to-roll printing of perovskite PV on glass.

The plan is backed by two partnerships, one with the Eastman Kodak Company for roll-to-roll printing and another with glass and ceramics company Corning, for flexible glass. EMC's funding includes a $4 million research grant from the Solar Energy Technologies Office of the U.S. Department of Energy.

EMC's CEO Stephan DeLuca recently stated, while speaking in a webinar hosted by the U.S. Manufacturing of Advanced Perovskites (U.S. MAP) consortium, that if the technology works, an eight-station roll-to-roll machine could produce 4 GW of perovskite PV material per year. The capital cost of the EMC project would be around $100 million ' $25 million per gigawatt of output capacity ' based on perovskite with 20% conversion efficiency, said DeLuca, far lower than the projected cost of $400 million per gigawatt for silicon PV capacity suggested by the chief executive.

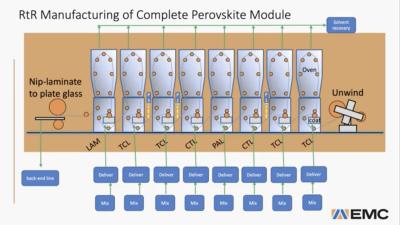

DeLuca unveiled the process diagram at the top of this story, showing flexible glass moving from right to left with eight stations printing transparent conductive layers (TCL), charge transport layers (CTL), a perovskite absorption layer (PAL), and laminating glue (LAM). Ink tanks are shown in blue at the bottom. On the left, the flexible perovskite-coated glass is laminated to plate glass. Ten separate lines would then make PV modules from the laminated plate glass.

EMC is conducting tests of a roll-to-roll pilot line at Kodak's facility in Rochester, New York State.

EMC's website states: 'At Kodak, we manufactured film products up to 1.5m wide and as fast as 1,000 feet per minute'. While some Kodak film products had 15 layers, perovskite PV printing would reportedly require only six to eight layers, with the line operating at a much slower 100 feet per minute.

EMC says challenges have included identifying the right perovskite inks to use, the correct inks to use for other layers, and avoiding the need for a long residence time for annealing in an oven, as the latter would slow line speed.