Stanford researchers stabilize rare form of gold using perovskite material

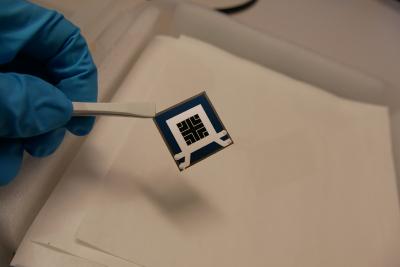

Stanford researchers have found a way to create and stabilize an extremely rare form of gold that has lost two negatively charged electrons, denoted Au2+. The material stabilizing this elusive version of the valued element is a halide perovskite. Surprisingly, the Au2+ perovskite is also quick and simple to make using off-the-shelf ingredients at room temperature.

"It was a real surprise that we were able to synthesize a stable material containing Au2+—I didn't even believe it at first," said Hemamala Karunadasa, associate professor of chemistry at the Stanford School of Humanities and Sciences and senior author of the study. "Creating this first-of-its-kind Au2+ perovskite is exciting. The gold atoms in the perovskite bear strong similarities to the copper atoms in high-temperature superconductors, and heavy atoms with unpaired electrons, like Au2+, show cool magnetic effects not seen in lighter atoms."