Researchers at Duke University have developed a method to create otherwise unattainable (or extremely hard to create) hybrid thin-film materials. The new technique could open the door to new generations of solar cells, light-emitting diodes and photodetectors.

The most common perovskite used in solar energy today, methylammonium lead iodide (MAPbI3), can convert light to energy as well as today's best commercially available solar panels. This can even be done using a fraction of the material - a piece 100 times thinner than a typical silicon-based solar cell. Methylammonium lead iodide is one of the few perovskites that can be created using standard industry production techniques, though it still has issues with scalability and durability. To truly unlock the potential of perovskites, however, new manufacturing methods are needed because the mixture of organic and inorganic molecules in a complex crystalline structure can be difficult to make. Organic elements are particularly delicate, but are critical to the hybrid material's ability to absorb and emit light effectively.

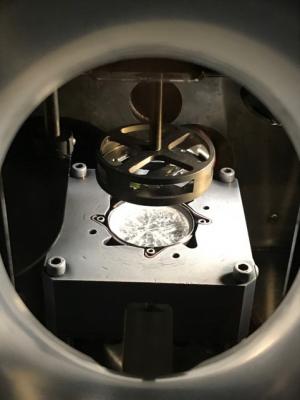

When a laser vaporizes a small piece of the frozen target, the vapor travels upward in a plume that coats the bottom surface of any object hanging overhead, such as a component in a solar cell. Once enough of the material builds up, the process is stopped and the product is heated to crystallize the molecules and set the thin film in place.

In the new version of the technology, the laser's frequency is specifically tuned to the molecular bonds of the frozen solvent. This causes the solvent to absorb most of the energy, leaving the delicate organics unscathed as they travel to the product surface. "The RIR-MAPLE technology is extremely gentle on the organic components of the material, much more so than other laser-based techniques," said the researchers. "That also makes it much more efficient, requiring only a small fraction of the organic materials to reach the same final product."

"While solution-based techniques can also be gentle on organics and can make some great hybrid photovoltaic materials, they can't be used for more complex and poorly soluble organic molecules.. With this demonstration of the RIR-MAPLE technology, we hope to open a whole new world of materials to the solar cell industry," explained the team. "We also think these materials could be useful for other applications, such as light-emitting diodes, photodetectors and X-ray detectors."