Researchers at University of Rome “Tor Vergata”'s CHOSE (Centre for Hybrid and Organic Solar Energy) and CNR-ISM Institute of Structure of Matter have deposited flexible perovskite solar modules without using toxic solvents, via blade coating in ambient air. 14% PCE was reportedly obtained through the optimization of coating parameters and the use of additives.

The scalable ambient air deposition of perovskite solar devices remains a major challenge of this technology. In addition, toxic solvents are regularly used in perovskite layer deposition, which can damage the environment and endanger the safety of potential production lines. In this recent work, the team managed to address these issues and fabricate sustainable flexible perovskite solar modules (flex-PSMs), in which all layers were deposited via a blade coating in ambient air without the usage of toxic solvents.

Double-cation Cs0.15FA0.85PbI3-xBrx-based perovskite was blade coated in two steps as the absorber and the coating parameters were optimized. The team found that proper drying of the first step is crucial to obtain high-quality perovskite films with the right phase of the perovskite. The researchers improved the morphology and limited the voids in the perovskite layer by additive engineering and obtained 14% efficiency.

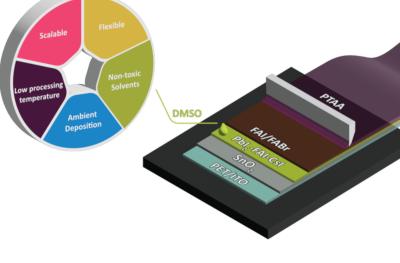

The team used the two-step blade coating method to deposit a perovskite layer at low temperature in ambient air using DMSO only as the solvent for the first step and isopropyl alcohol (IPA) for the second step.

Low-temperature deposition of DMSO-based ink was introduced to apply on flexible substrates. Previous works on single-step deposition of DMSO-based perovskite solution, using the blade coating technique required high substrate temperature (150 °C) or high annealing temperature ( 170 °C). In addition, the previously reported devices were fabricated under a nitrogen atmosphere.

The researchers fabricated flexible perovskite solar cells with a planar N-I-P device architecture of PET/ ITO/ SnO2/ Cs0.15FA0.85PbI3-xBrx / PTAA/ Au in ambient air with a relative humidity of 30-35%. Solar cells were blade coated on large substrates (5×7 cm2) but measured on small scale with 0.09 cm2 active area, and the champion device achieved 14.08% PCE.

The team presented in this recent work a fully-blade coated and flex-PSM with a 9.7×9.7 cm2 (94 cm2) aperture area. They stated that the process was proven to be transferable to larger substrates up to 13×13 cm2, and that further efforts should be focused on improving the performance of these ambient-air fabricated modules.