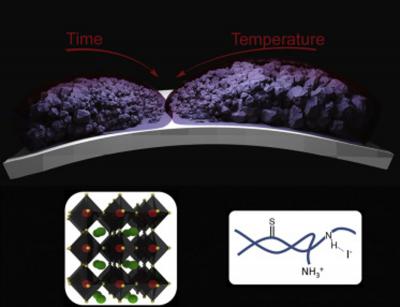

Researchers at the Department of Energy's SLAC National Accelerator Laboratory and Stanford University have used the lab's X-ray laser to watch and directly measure the formation of polarons for the first time. Polarons are fleeting distortions in a material's atomic lattice that form around a moving electron in a few trillionths of a second, then quickly disappear. Despite their transient nature, they do affect a material's behavior, and may even be the reason that solar cells made with lead hybrid perovskites achieve extraordinarily high efficiencies in the lab.

Polaron 'bubbles' of distortion form around charge carriers ' electrons and holes that have been liberated by pulses of light ' which are shown as bright spots here. Image by SLAC

Polaron 'bubbles' of distortion form around charge carriers ' electrons and holes that have been liberated by pulses of light ' which are shown as bright spots here. Image by SLAC

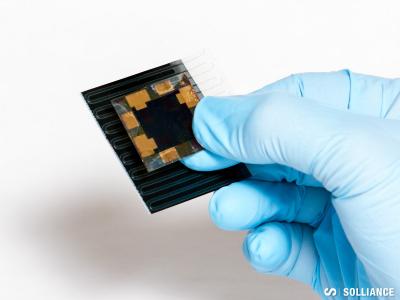

Perovskite materials are famously complex and hard to understand, according to Aaron Lindenberg, an investigator with the Stanford Institute for Materials and Energy Sciences (SIMES) at SLAC and associate professor at Stanford who led the research. While scientists find them exciting because they are both efficient and easy to make, raising the possibility that they could make solar cells cheaper than today's silicon cells, they are also highly unstable, break down when exposed to air and contain lead that has to be kept out of the environment.