Researchers at the Japan-based Okinawa Institute of Science and Technology Graduate University (OIST) have developed perovskite-based solar devices using a new perovskite material that is stable, efficient and relatively cheap to produce.

This material has several key features. First, it is completely inorganic ' an important shift, because organic components are usually not thermostable and degrade under heat. Since solar cells can get very hot in the sun, heat stability is crucial. By replacing the organic parts with inorganic materials, the researchers made the perovskite solar cells much more stable. 'The solar cells are almost unchanged after exposure to light for 300 hours,' says Dr. Zonghao Liu, an author on the paper.

All-inorganic perovskite solar cells tend to have lower light absorption than organic-inorganic hybrids, however. This is where the second feature comes in: The OIST researchers doped their new cells with manganese in order to improve their performance. Manganese changes the crystal structure of the material, boosting its light harvesting capacity. 'Just like when you add salt to a dish to change its flavor, when we add manganese, it changes the properties of the solar cell,' says Liu.

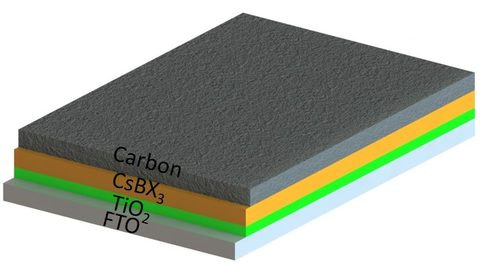

In these solar cells, the electrodes that transport current between the solar cells and external wires are made of carbon, rather than of the commonly used gold. Such electrodes are significantly cheaper and easier to produce, in part because they can be printed directly onto the solar cells. Fabricating gold electrodes, on the other hand, requires high temperatures and specialist equipment such as a vacuum chamber.

The OIST team will continue to work on these new cells' efficiency and durability, and is also developing the process of fabricating them on a commercial scale.