The Solar Energy Research Institute of Singapore (SERIS) upgrades equipment towards industrial production of perovskite-silicon tandem solar cells

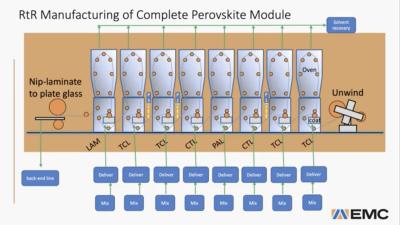

The Solar Energy Research Institute of Singapore (SERIS) at the National University of Singapore (NUS) announces that it will upgrade its "Spatial Atomic Layer Deposition" (SALD) equipment. SoLayTec and SERIS have been working closely together for over a decade in the field of silicon solar cells. Recently, SERIS stated that SoLayTec will upgrade its existing ALD system using the latest technology of SALD BV, a Dutch technology start-up, for development of scalable perovskite-silicon tandem solar cells.

"Upgrading to the new SALD equipment brings us significant advantages," explains Dr. Shubham Duttagupta, Deputy Director of the Next-Generation Industrial Solar Cells & Modules Cluster at SERIS. The Dutch company SALD BV has developed a patented technology for applying precise coatings on an industrial scale that can be as thin as a single atom. An atomically thin coating, as can be achieved with the SALD technology, can make the cells significantly more robust. SERIS wants to take the leap “from lab to fab” with the new SALD machine.