UK-based Ossila provides components, equipment and materials to enable faster and smarter organic electronics research and discovery. Ossila provides both materials and equipment for perovskite researchers, and the company's lead perovskite scientist, Dr. Jonathan Griffin, was kind enough to answer a few questions we had for him.

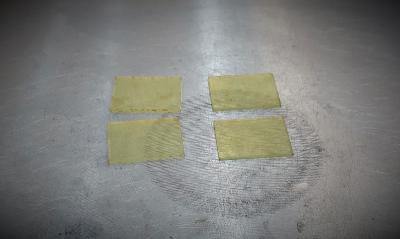

Thanks to improved knowledge about salt-solvent interactions, single crystals of perovskites can now be grown. Pictured above are several single-crystal MAPbBr perovskites, alongside the seed crystals used to grow these crystals

Thanks to improved knowledge about salt-solvent interactions, single crystals of perovskites can now be grown. Pictured above are several single-crystal MAPbBr perovskites, alongside the seed crystals used to grow these crystals

Dr. Griffin holds nearly a decade of experience working in organic photovoltaic research and over 5 years of working with perovskites. At Ossila, Jonathan works on technical support for several material ranges, including perovskites, organic photovoltaics, graphene and other 2-D materials. He is also involved in the development of new test equipment and product ranges. Prior to this, he worked in a postdoctoral research position at the University of Sheffield.

Q: Thank you for your time Dr. Griffin. Can you detail for us Ossila's perovskite product range in general?

Our perovskite range can be split into materials and test equipment. The biggest of these are the perovskite precursor materials ' we have focused on providing a wide range of organic salts required for fabricating a variety of different perovskite structures. Additionally, we have a selection of interfacial layers for both hole-transporting and electron-transporting layers as these are often critical for obtaining high performance devices. Finally, we have our premade inks, these are designed to simplify the process of developing perovskite solar cells for new researchers in the field.

On the other hand, our range of perovskite test equipment includes supporting products such as our laboratory equipment, our test-and-measure systems, and our substrate systems (which were recently recognized by the Institute of Physics with an Innovation Award). These ranges help perovskite researchers not only get the materials they need, but also the equipment required to process and measure thin-films and devices. Recently, we also launched our lab-scale slot-die coater (after four years of development!), and with this we aim to fundamentally change the lab-to-fab transition by enabling many more researchers to access scalable, high-performance coating systems.

Q: Ossila offers both Perovskite precursors and inks. What are the most common applications for your inks?

Our precursor inks are mostly used for the fabrication of solar cells. The initial idea behind the inks was to provide researchers who are new to the perovskite field with a simple solution to the fabrication of the perovskite layer itself. Our initial work taught us that there are multitude of factors influencing how well a perovskite layer can perform - these factors are not only due to the processing steps used, but also the preparation of the inks and the precursors themselves. Our goal was to try and eliminate as many of those factors as possible, by providing researchers with a stable ink produced from materials that had been tested in working systems. Combining these inks with the guides we have on fabricating devices and the customer support we provide, we hoped to be the catalyst that enabled people with no prior perovskite fabrication experience to reach a level where they could produce reference devices ' with a quality comparable to those in literature.

Perovskite solutions can have a variety of different compositions which control the final chemical structure and influence the way that the films form. The ink pictured above uses a mixed-halide precursor containing methylammonium iodide, lead chloride, and lead iodide to allow for the formation of MAPbI3-xClx perovskite in an inert atmosphere.

Q: Can you tell us what is your top-selling perovskite material? What is it used for and how?

Methylammonium Halide and Formamidinium Halide are our most popular materials. These are what I like to call the 'workhorses of perovskite research', as they are used for making several different precursor formulations - ranging from the early MAPbI3 structures, to the high performance mixed-halide structures, such as (FAPbI3)3-x(MAPbBr3)x. We sell these materials in a highly-purified state, which have the impurities (often left over in the synthesis of these materials) removed. Typically, you would see hydroiodic acid or hydrobromic acid left over in small percentages, which can vary among different batches. The presence of these impurities has a dramatic effect on the formation and conversion of the perovskite film. Even a variation of half a percent can cause a dramatic change in the efficiency of the final device! By having a pure source of these precursor materials, it is possible to add an exact percentage of these acids back into the ink you make, thus improving the consistency of your results.

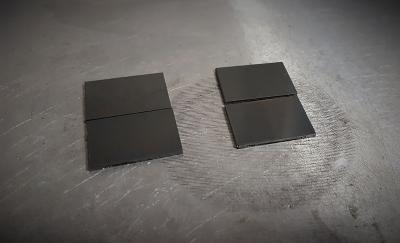

Perovskite precursor materials must undergo a conversion process, in which the material converts from the initial salts to the final perovskite. The image above shows a film of 3MAI:PbCl2 after deposition via spin coating. The image below shows the same films after two hours of thermal annealing - where it undergoes conversion to MAPbI3-xClx.

Q: In the past several years Perovskites have been very popular, mostly for solar applications. What can you tell us about changes in the perovskite market in recent years?

The changes in perovskites and its surrounding fields over the past 5 years has been extraordinary. Although there have been some exciting new applications for perovskites, the biggest changes have still come about through the application of these materials in solar cells. The biggest shift has been in the range of materials that are used in perovskite devices ' initially, almost all work was focused upon the standard mesoporous titanium oxide/MAPbI/SpiroOMeTAD stack, which has become so widespread through the perovskite community. In recent years, we have seen a big shift away from this, especially for people aiming for higher power conversion efficiencies and lifetimes. We now see these highly-complex formulations incorporating mixed-halide triple-cation precursors, and 2d/3d hybrid structures. Moreover, we can also see substantial changes in the approach to interfacial layers, with the shift away from mesoporous titanium oxide to planar architectures - where other materials (such as tin oxide) can be used to push that efficiency just that bit higher. It has been this shift that has seen the massive changes in power conversion efficiency, and the stability of devices.

Q: Solar cells are obviously the most interesting perovskite application. When do you expect to see commercial perovskite solar panels on the market?

Currently, the field is still very young. Even with the huge progress that has been made in both efficiency and lifetimes, there are still problems with consistency of results and scaling-up of processing. I think the first commercial applications will be in-tandem devices with silicon solar cells to try and boost the power conversion efficiency. A rough estimate might be around 5 years before we see something like this enter large-scale production. However, there are potentially huge stumbling blocks that could slow this down, such as adapting the processing techniques to a scalable deposition method and ensuring the lifetime of the perovskite layer is equal to that of the silicon cell itself.

There could also be commercial applications in display technology, which may happen sooner than we think. This field has often been quick to adopt novel innovative technologies such as organic light-emitting materials, and recently with quantum dot technology. It would not surprise me if the first commercial applications we see will be an initially niche, but high-growth component for something like a smartphone/television, rather than a solar panel.

Q: Can you identify other popular perovskite applications, other than solar?

Many applications have been emerging over the past few years for perovskites. The most obvious is their use in light-emitting diodes, as the emission can be broadly tuned by changing the ratio of halides in the perovskite structure. The use of 2d perovskites utilising organic cations with long side-chains has resulted in incredible photoluminescent quantum yields. Due to this broad tunability in absorption and emission. The improved knowledge in processing these materials (a result of increased research into solar cells) has shown that large single crystals of these materials can be made quite easily. These single crystals are beginning to see use in applications (such as lasers) which will likely open whole new avenues of research into perovskite materials. The high mobility of the materials, coupled with high quantum yield, brings forth the intriguing possibility of direct electrically-pumped lasers ' a hugely exciting, but perhaps longer-term target.

Q: How do you see the perovskite market developing in the next 3-5 years? What are the major challenges ahead? How do you see Ossila's part in the future perovskite market?

The next few years will likely involve further improving the stability, reproducibility, and scaling of perovskite films and devices, as this is the biggest hurdle for commercialisation of these materials.

Over the past year, there has been promising work in the integration of 2d structures into perovskite films, along with the replacement of spiro-OMeTAD layer with materials that require lower doping (and result in less oxygen and water ingress into the perovskite). Improvements in reproducibility have also occurred thanks to the development of processing techniques, such as solvent quenching, which allows finer control over the formation of the perovskite film. Additionally, for scaling the fabrication of perovskite devices, we are starting to see more work using techniques such as spray deposition, bar coating, and slot-die coating.

Ossila are hoping to provide as many researchers as possible with the knowledge, tools, and materials required to work on these problems. We firmly believe that getting these three things into the hands of researchers is the best way to see advancements in science. As the majority of the Ossila team come from a research and development background, we also have a personal interest in helping researchers succeed.

Thank you for your time and interesting information Dr. Griffin, I wish both you and Ossila the best of luck!